.

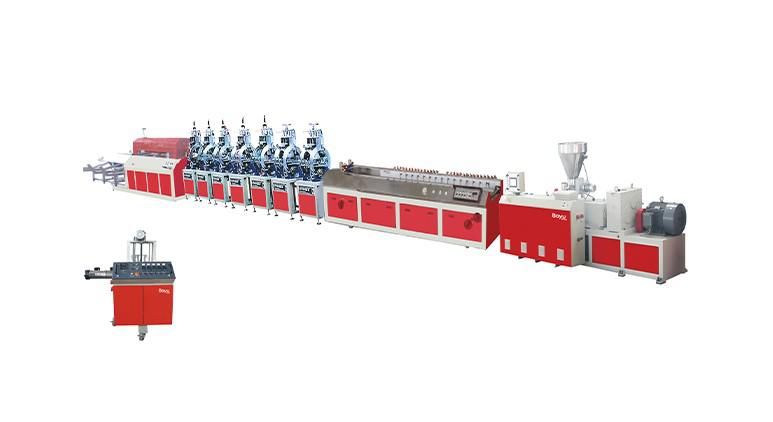

Extruder machines are used in various industries, from manufacturing to warehousing. Learn about what an extruder machine is and how it can help your business!

Extrusion Machines and Their Application

Extrusion machines are used in various industries to create products ranging from food and beverage containers to floor-making devices. This powerful technology has increased efficiency and productivity in many businesses, making it an essential part of any production line. Here we'll take a closer look at extrusion machines and their key applications.

Extrusion machines work by forcing heated plastic material through dies or nozzles, forming the final product. The most common type of extrusion machine is the injection molding machine, which produces plastic products such as flooring production. Another popular application for extrusion machines is the production of floor-making devices, such as single screw extruder machines, T-die machines, calendaring machines, traction machines, floor cutting machines, and automatic flipping & stacker machines. In all cases, extrusion machines play an essential role in ensuring high-quality products at fast speeds.

There are several various benefits to using an extrusion machine in your business. Extrusion machines are incredibly efficient; they can produce large quantities of products at high speeds with minimal waste. In addition, extrusion machines are versatile; they can be adapted to produce various products.

Benefits of Using an Extruder PVC Machine

An extruder PVC machine can be a valuable tool for businesses. Here are some of the benefits you can expect to see:

- Reduced production time. Extruders can help reduce the time it takes to produce products by automatically adding material to the output stream.

- Increased output quality. Extruders produce higher quality products due to their ability to handle delicate materials with precision.

- Reduced waste. Because extruders can create products with specific shapes and dimensions, they can help reduce the amount of waste produced during product production.

- Enhanced customer satisfaction. Customers who receive products that have been produced using an extruder machine are more likely to be satisfied with them than those who receive products produced using other methods.

Going to the cinema alone is good for your mental health, says science

Going to the cinema alone is good for your mental health, says science

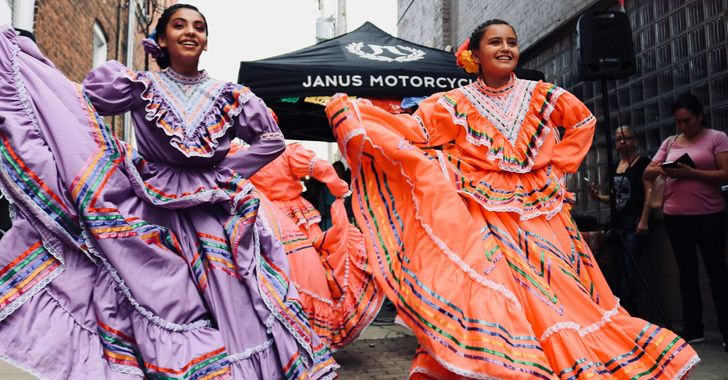

women in street dancing

Photo by

women in street dancing

Photo by  man and woman standing in front of louver door

Photo by

man and woman standing in front of louver door

Photo by  man in black t-shirt holding coca cola bottle

Photo by

man in black t-shirt holding coca cola bottle

Photo by  red and white coca cola signage

Photo by

red and white coca cola signage

Photo by  man holding luggage photo

Photo by

man holding luggage photo

Photo by  topless boy in blue denim jeans riding red bicycle during daytime

Photo by

topless boy in blue denim jeans riding red bicycle during daytime

Photo by  trust spelled with wooden letter blocks on a table

Photo by

trust spelled with wooden letter blocks on a table

Photo by  Everyone is Welcome signage

Photo by

Everyone is Welcome signage

Photo by  man with cap and background with red and pink wall l

Photo by

man with cap and background with red and pink wall l

Photo by  difficult roads lead to beautiful destinations desk decor

Photo by

difficult roads lead to beautiful destinations desk decor

Photo by  photography of woman pointing her finger near an man

Photo by

photography of woman pointing her finger near an man

Photo by  closeup photography of woman smiling

Photo by

closeup photography of woman smiling

Photo by  a man doing a trick on a skateboard

Photo by

a man doing a trick on a skateboard

Photo by  two men

two men  running man on bridge

Photo by

running man on bridge

Photo by  orange white and black bag

Photo by

orange white and black bag

Photo by  girl sitting on gray rocks

Photo by

girl sitting on gray rocks

Photo by  assorted-color painted wall with painting materials

Photo by

assorted-color painted wall with painting materials

Photo by  three women sitting on brown wooden bench

Photo by

three women sitting on brown wooden bench

Photo by

Photo by

Photo by  Photo by

Photo by  Photo by

Photo by  Photo by

Photo by

people sitting on chair in front of computer

people sitting on chair in front of computer