Walmart utilizes strategic and innovative management of its supply chain in order to reap the financial benefits of efficiency and accuracy within it. To manage its supply chain, Walmart practices extremely tight management and control over manufacturing, inventory, and distribution. The company synchronizes these elements through various electronic interchanges which aid in communication between differing segments of the chain. Although Walmart, like other large firms, outsources many of its products, it employs close relationships with important vendors across the world. These partnerships are crucial, as they deter miscommunications and promote productivity among both entities. For example, Walmart’s relationship with Proctor and Gamble has aided in ensuring swift product replenishment in all of its locations. In addition, Walmart takes advantage of tactics like cross-docking and a hub-and-spoke distribution networks to push goods speedily through the chain. Because supply chains include multiple firms with potentially conflicting objectives, it is possible for issues to arise that negatively impact the company. If Walmart and its vendors do not coordinate their endeavors properly, a bullwhip effect could ensue. This means that a buildup of inventory occurs resulting in decreasing revenue for both retailers and manufacturers. In addition, without proper communication and control in a supply chain, there could be delays in delivering goods or perhaps even quality control problems. One conflict mentioned in the case study centered on Walmart’s suppliers outsourcing without Walmart’s consent or knowledge. When a fire killed 112 workers in one of these subcontracted factories, it reflected negatively on the retailer. Walmart solved this conflict through enacting a zero tolerance policy on suppliers subcontracting. Walmart has been extremely proactive in increasing product availability and lower merchandise acquisition and transportation costs. In the 1980s, Walmart partnered with Proctor & Gamble to build one of the first collaborative planning, forecasting, and replenishment systems. This system linked P&G to Walmart’s distribution centers, so that when inventory levels of P&G products were low, the vendor was alerted to ship more products. In addition, the software allowed Walmart to track when a P&G shipment arrived at a distribution warehouse, which granted the retailer the ability to better plan its shipments to stores. This coordination resulted in savings for both firms and was beneficial to customers, as it allowed for lower prices. Additionally, Walmart drove the adoption of UPC barcodes and pioneered the use of EDI for computerized ordering from vendors, again fostering great efficiency. The retailer is able to ship products from its warehouses to stores within a day’s travel through its usage of hub-and-spoke networking and cross-docking. The goods are transported using a relatively speedy fleet of trucks, and this short travel time makes the company much quicker to deliver merchandise to locations across the world. Walmart was one of the earliest adopters of RFID technology, and today tests its usefulness for apparel products. In the future, if the retailer chooses to expand this technology to other products, it could see a faster flow of goods throughout the chain.

Recommended for you

Walmart: Masters of Supply Chain

A look into some of the highlights of Walmart's efficient logistics system

Subscribe to our

Newsletter

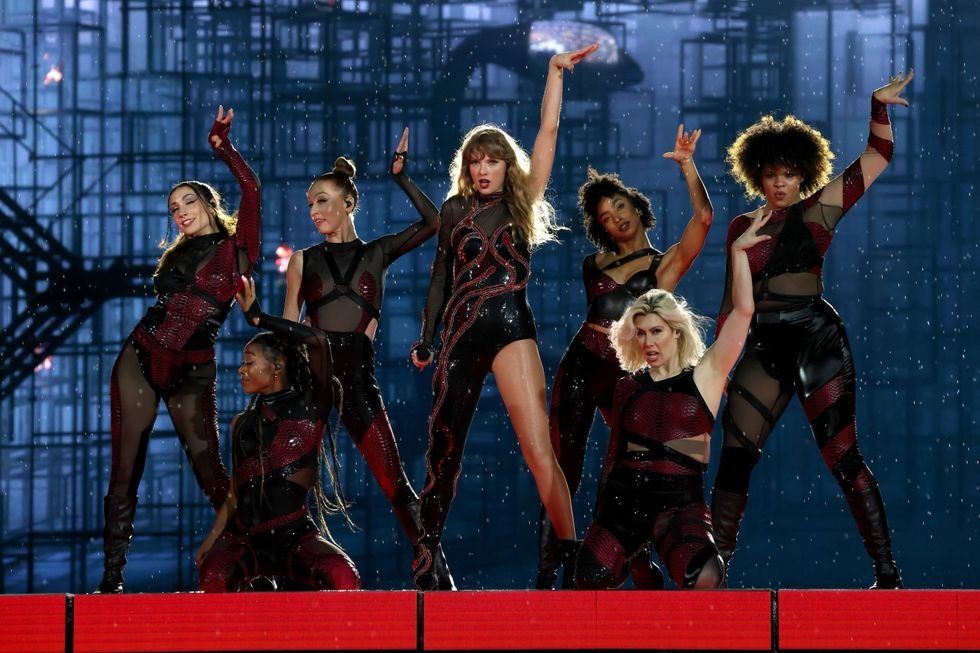

A three-and-a-half-hour runtime. Nine Eras. Eleven outfit changes. Three surprise songs. Zero breaks. One unforgettable evening. In the past century, no other performer has put on an electric performance quite like Taylor Swift, surpassing her fans ‘wildest dreams’. It is the reason supporters keep coming back to her shows each year. Days later, I’m still in awe of the spectacle ‘Miss Americana’ puts on every few days in a new city. And, like one of Taylor’s exes, has me smiling as I reminisce about the memories of the night we spent together.

Swifties from around the Delaware Valley flooded South Philadelphia for a three-day Swift-a-palooza, with many bejeweled in ‘style’ from head to toe, symbolizing the eras of the Reading, Pennsylvania natives' decade-long career in the music industry. Fans camped out overnight just to get their hands on the tour's well-made merchandise to commemorate the upcoming evening. You could feel the anticipation building inside and outside the sold-out stadium as Swift was set to take the stage hours from showtime.

Fresh off a Grammy nomination for song of the year, GAYLE was first to open the tour with seven genre-blending selections that had a large majority of fans rise to their feet. The ‘abcdefu’ singer had such poise and pureness in her vocals, and the chemistry between her bass player and drummer was unmatched. My favorite part of her set was a rock-infused tribute to Elton John's 1973 iconic hit, ‘Bennie and the Jets’. It’s a tough song to cover, and GAYLE did it justice and more.

Phoebe Bridgers followed moments later, dressed alongside her band in their signature black skeleton suits. Bridger's folk-infused hits were a delight to hear live, and I love the storybook visuals that portrayed how each song felt like a new chapter in her life. Matt Healy, frontman of the 1975 and Swift’s rumored-to-be boyfriend, was on guitar for the entire set, which was a surprise to the audience.

With a 46-song set spanning the ‘eras’ of Taylor, the twelve-time Grammy Winner took fans on a musical journey through her dozen album discography, beginning with Lover and ending with her latest album, Midnights, released late last year. It’s been nearly five years since Swift performed back in her hometown with her Reputation Tour in 2018. Since then, she has released four projects and two re-recordings of her albums Fearless and Red, each of which has never been performed live until now. In a previous interview, Swift said she wants fans who have seen her previous shows to have a completely different feeling each tour, and this statement couldn’t ring more true. She knows what the fans want ‘all too well’. And unsurprisingly, Swift and her team have outdone themselves once again. The tour is a testament to Taylor’s pure genius and a creative visionary mind, bringing her songs and sets to new heights in imaginative fashion.

It’s so fascinating to see live how strong the connection is between Swift and her fans. Unlike some of her colleagues in the industry, Taylor has songwriting credits on each of her timeless songs, focusing on topics such as heartbreak, depression, and childhood innocence. The personal anecdotes and honesty in her music make fans feel like they know her through her art of songwriting. Even with over seventy-thousand in attendance, Taylor made each fan feel like they were seen and heard as she gracefully danced her way around the stage, waving and blowing kisses to everyone she could see in her field of vision. From beginning to end Swift had such swagger and charisma on stage. She was born to entertain, and the audience was bedazzled by her presence.

Fans had immense energy from start to finish, singing every word and ad-lib as if they wrote it themselves. Mid-way through the show, fans gave Swift a rapturous ten-minute standing and cheering ovation that was loud enough to hear miles down the road. Taylor matched the energy and more and was filled with so much vigor and vibrancy in her performance. She took time throughout the show to speak directly to her fans with humble, down-to-earth interactions.

“Hi, I’m Taylor. Whether or not you intended to, you’ve ended up at my hometown show. I grew up right down the road.”, Swift said. Wearing a sparkling gray dress and matching boots, Taylor kicked off the show in her Lover Era with ‘Miss Americana and the Heartbreak Prince’ as her backup dancers paraded around her in elegant peacock-esque outfits. The visuals made me feel as if I was in the clouds as Swift danced on a box that rose above the stage. Swift seamlessly transitioned into her hit ‘Cruel Summer’, and the stage was filled with purple and pink aesthetics that looked like milky ways in the night sky. My favorite song of the Lover Era is by far ‘The Man’, a song about the mistreatment between men and women in our culture. With a creative three-story office set, upbeat liveliness from Swift and her suit-wearing dancers, and dramatic facial expressions, it felt as if I were inside one of her music videos.

Each Era felt perfectly timed and refreshing with new costumes, vibrant aesthetics, set design, and song choices, with the production quality of a broadway play. While I thought each Era brought something special, my personal favorite was Red. Sprinkled in with upbeat jams like ‘I Knew You Were Trouble’ and ‘We Are Never Getting Back Together’, Taylor brought Phoebe Bridgers back on stage to sing their duet of ‘Nothing New’. Their soul-stirring voices were succinct and in perfect harmony as they ricocheted throughout the stadium, and I don’t think there was a dry eye in the building after it was over. Taylor ended the set with her ten-minute version of ‘All too Well’, and the song gave me chills to hear live. The LED light-up bracelets given to every concert-goer transformed the stadium into a sea of red that looked like twinkling stars. If this is what heaven feels like, then I can’t wait to go.

The Eras tour is a dazzling delight, a first-class concert experience that is pure euphoria, bliss, and happiness. It’s a must-see show that will make everyone who witnesses it leave feeling ‘22’.

A Few Thoughts Every College Freshman Has

The transition into adulthood is never easy

Today I started my third week of college at Minnesota State Moorhead. I have survived welcome week, finding my classes on the first day, and being an awkward loner in the dining hall. Even though I have yet to be here for a month, I have already experienced many thoughts and problems that only a new college student can relate to.

1. "Unlimited Freedom!"

This is probably the first thought anybody heading off to college has. As a high school senior, that independence you've been dreaming about since you were a freshman is finally a reality! Without your parents' constant supervision, you can now midnight order that pizza you were thinking about in ethnics class. Not to mention unlimited sleepovers with your friends, late nights trips on the weekdays, and unlimited trips to Target.

2. "Dorm Life!"

I remember when I first moved into my dorm, my roommate and I couldn't wait to sleep in our new home. We spent months coordinating and planning, and the day had come for us to officially be residents! Living in the dorms provided us with a great opportunity to meet people and make a million new friends! We couldn't wait!!

3. "Never mind, where is my apartment?"

Soon reality sets in, and you accept the dorm life isn't wait you paned it out to be. Those first few months are spent moving your seven fans around the room, trying to find the perfect airflow to avoid a mild heatstroke. Your collectables and your roommate's belongings are piling up on any open space they can find. Not to mention climbing fourteen flights of stairs to your room is enough to convince yourself you don't need the gym.

4. "Whose idea was this 8 AM?"

Nothing fills a college student with daily regret like the impact of an early morning class. Getting up early to get classes out of the way and leave the rest of your day free all seemed like a good idea a few months ago. Now every morning you pick yourself up, and stumble across campus in your onesie muttering curses to yourself.

5. I'm so looking forward to that nap."

After a few short weeks, college starts to take a mental tole on the student. You've wrote a novel full of notes, read the bible for your religions class quiz, and created a gallery for the campus art studio. From the moment you leave your bed every morning, all you can think about is "gee I sure am excited for that three hour nap in my sauna dorm room."

6. "I don't have the brain capacity for this"

Transitioning from the load of homework in high school to college could be a job on its own. After three days on campus, you've already received the workload you had all four years in high school. You spend hours with your notebook religiously, and are starting to wear the letters off your computer's keyboard. You've come to accept that college requires the same time commitment as full time job.

7. "Wow, college is great"

Yes, college does have it's unforgiving challenges, but where would we go in life if we were not forced to find our true potential? The homework load is overwhelming, and a time where you are not exhausted is rare. However, you are exposed to thousands of new individuals to meet, have unlimited independence to experience with, and a wide variety of new sports and clubs to try out. College is the time you take to find yourself, and form who you will be in the future.

"Make sure to get involved when you're in college!"

We've all heard some variation of this phrase, whether it came from parents, other family members, friends, RAs, or college-related articles. And, like many clichés, it's true for the most part. Getting involved during your college years can help you make friends, build your resume, and feel connected to your campus. However, these commitments can get stressful if you're dealing with personal issues, need to work, or aren't sure how to balance classes and everything else going on during the semester.

Luckily, many colleges offer a number of ways to take part in campus and community life, without forcing you to dedicate all of your time to these organizations. Here are a few ideas!

1. Look into Housing and Dining.

Many first-year students start off college life in residence halls, and the Housing & Dining network throughout campus often provides multiple opportunities for students throughout the year. Many buildings have student community councils that work to create policies and events that make the dorms a more welcoming home for residents. Becoming a community assistant (or the students who work the desks at the front of many halls) is another easy way to have a consistent, well-paying job only minutes away from your room.

If you really enjoyed your housing experience, consider applying to be an RLA, or, if the school offers it, help to teach the first-year community. You'll get the chance to help support new and returning students over the year, and many of these positions also cover major costs like board and meal plans.

2. Pay attention to campus postings.

This advice is more obvious, but it still gets overlooked a fair amount. Even on a busy day, taking the time to stop around campus and look at the flyers advertising clubs and events can draw your attention to something that you never would've noticed otherwise. Students on many campuses also chalk the sidewalk to catch students' attention while they walk to class. Just make sure that the event you're interested in hasn't taken place already!

3. Find common interest groups.

One way to find friends and get involved is to focus on what you're passionate about. Have you always loved to sing? Do you enjoy playing video games? Is photography your favorite past-time? Have you always wanted to join Greek life? Whatever you love devoting your time to, chances are there are organizations around school who are focused on the same thing. Check the student life section of your university's website, or stop by a student organization fair at the beginning of the semester.

4. Join an intramural sports team.

If you're the athletic type, you've probably heard of intramural sports. Often offered through the Rec Center or the residence halls, most colleges often offer various indoor and outdoor sports to take part in throughout the year. Personal favorite? Mini golf.

5. Work on a cause that you care about.

Whether you're passionate about a political group, a social cause, or a religion, working with people who value beliefs similar to yours can be an easy way to meet people, get a better sense of your own identity, and promote causes that are important to you. Look into getting involved with College Democrats, Republicans, or whatever party that you belong to. Find a club that supports social issues, from women's rights to protecting the environment. If you're religious, look into student organizations based on your faith.

6. Join a club related to your major.

Even if you're not entirely sure what you want to do after school, finding a club or organization related to your field of studies can benefit you long after you leave the classroom. From career-related workshops to conferences to professional connections, these groups have a lot to boast.

7. Get an on-campus job.

If you have the time, need to work, or want to save a few extra dollars, finding a job on or near campus is a time-effective way to build up your bank account and gain work experience. Check in your residence hall (see #1), at local businesses and offices, or make an appointment with your school's career center.

8. Volunteer.

When you're caught up in school life, it can be hard to think about the bigger picture. Volunteering your time to people (or animals/an environment) in need puts things in perspective and allows you to feel good while making a positive difference. Check if your college town has a volunteer page, or look up local organizations requesting help.

Best of luck this year! Get out, and get busy.

9 Reasons Why Friends Are Essential In College

College without friends is like peanut butter without jelly.

In college, one of the essential things to have is friends. Yes, textbooks, a laptop, and other school supplies are important but friends are essential. Friends are that support system everybody needs. The more friends you have the better the support system you have. But you also have someone to share experiences with. And don’t settle for just one or two friends because 8 out of 10 times they are busy and you are studying all alone. Or they have other friend groups that do not include you. Don’t settle for just one or two friends; make as many friends as you can. After the first couple of weeks of college, most friend groups are set and you may be without friends.

1. You need people to hang out with.

Friends are almost an essential part of time. Friends make everything better; games, parties, movies, even studying. Especially in college, there is not much to do after classes. Having a few people to hang out with at night will make any night better. This will probably create lifelong friends and memories.

2. You don’t want to be stuck alone eating lunch or dinner.

One of the worst things in college is sitting alone in a huge cafeteria or feeling too awkward to go to the cafeteria by yourself. Most of the time being by yourself sucks unless you like a lot of alone time. If you're not in class, you are most likely eating food somewhere. Meals are always more enjoyable with other people.

3. Weekends suck without anyone to share them with.

In college, it is very rare to have classes on the weekends. So what else is there to do? Hang out with friends, go to football games and other sports, shopping, and anything else you can think of. Although, you wouldn't do these things by yourself usually. Having friends on the weekends will make your weekends so much more enjoyable, rather than watching a bunch of people have fun from your dorm window.

4. College will be miserable for you.

Having no friends might actually make you cry. Not having anyone to do anything with is actually pretty upsetting and after a while it might make you upset, depressed, or even stressed out. You don't want to remember college as a horrible time because you didn't have a lot of friends. You want to remember the good times and be able to share them with others.

5. Finding a roommate for the following year will be impossible.

One of the worst things in college is having a roommate you do not get alone with. Sure you can apply for another random roommate the following year, or you can have a friend to room with. But not having close friends, it will be hard for you to find a roommate. If you aren't close with a person but they are close with someone else, chances are they will room with the person they are close with over you.

6. You need someone to talk to about personal stuff or homework that isn’t your mom.

When struggling with something it is always easy to spill your guts to someone to relieve the stress. Half the time in college it is your mom. But there are somethings that you don't feel comfortable saying to your mom-- unless you are extremely comfortable/close with your mom. You also don't want to be the person known for excessively calling your mom for everything, they don't go to college with you.

7. Classes will be boring and quiet for you if you don’t know anyone.

Walking into any class and not knowing anyone is awkward. Going through the semester not talking to anyone is even worse. You'll most likely be bored as hell, and probably start to fall asleep-- unless the lecture is really interesting. Plus you will most likely be the one person who never has a partner and has to ask the professor for a partner.

8. Walking around campus is just awkward.

Walking around not knowing anyone is weird. It may feel like you don't belong there and you may just want to hurry up to go hide in your dorm. All these other students are walking around talking to their friends while you just walk with your face buried in your phone trying to avoid eye contact with anyone and everyone.

9. Homework help and study buddies do not exist.

When trying to study/ do homework it is always helpful to have something to do it with. Study buddies are a great tool in college because if you don't understand something chances are they do. You can't call up your professor at 2 a.m. trying to ask them a question but, you can call up a friend to ask them the same question. Friends are a great study tool.

For a moment your world is spinning. The phone alarm has just scared you awake and you’re flooded by daunting thoughts of the day ahead. You have three assignments due and little time to work on them because of your job. You’re running late because you’ve hit snooze one to many times after yesterday’s long hours. You dizzily reach for a hoodie, craving its comfort, and rush for a speedy exit, praying you will have time to pick up coffee. Does this sound familiar?

You have just made a big mistake. How we dress can really affect our day. Amongst the array of daily responsibilities you have as a college student, worker, friend and partner, the last thing you want to do is dress up in the morning. Makeup and heels are likely last on your long list of priorities however, they can be essential weapons to fight off the zzz’s you’re craving and conquer your day.

Here are some reasons why making the effort to dress up is worth your time:

1. Comfort

Often the more comfortable we are, the sleepier we get. In soft, oversized clothes we desire sleep. It’s like being tired even after getting nine hours of rest. If you put yourself into a cozy environment, by default you feel relaxed. The same goes for clothes. Now, that doesn’t mean you’re tight skirts and Spanx are necessary as even beautiful clothes can be loose and practical. That groggy feeling you have can even be wiped away by a splash of makeup. Your winged liner and fake lashes aren’t daily essentials, but a touch of blush and swipe of mascara can brighten your eyes and enhance your focus.

2. Confidence

When you leave your home in sneakers, you walk, but when you leave in heels, you strut! Looking nice just makes you feel better. When you’re well put together, some of the day’s obstacles become less difficult. In wedges or thick healed booties, you are not only standing taller, but you can also stomp all over the problems and difficult people that come your way. (Not literally—heels don’t work in jail!) Obviously, heels aren’t practical for every environment, but that’s no excuse to be boring. Spicy flats and silly sandals can have the same bold and beautiful effect. When you look better, chances are you will feel better about yourself.

3. Surprises

My mom told me long ago, “You better look good; you never know who you’ll run into!” Life throws us an annoying amount of curve balls. On an otherwise routine day, you may run into an ex or “frenemy.” Your sweatshirt may leave you with regrets but a sexy sophisticated ensemble will leave the regrets with them! At work, your bosses may decide it's time for an unplanned office picture. Congratulations, your sweatpants will forever be featured in the office picture day all over your favorite social media sites! The curve ball options are endless, so isn’t it better to always be prepared?

4. Self Esteem

Admit it, compliments are nice. When someone admires your earrings or tells you that you’re beautiful, does it not brighten up your day? We make impressions on the people around us whether we realize it or not. We are identified visually—it’s human nature. Our style and self-presentation is a part of who we are. Make your outfit reflect your personality; think of it as an extension of yourself. Standing out rather than blending in will inevitably bring greater opportunities and successes to your life, it might even give you a leg up on that promotion at work. Sometimes that extra moment spent adding flair to your visual persona is worth it in the end.