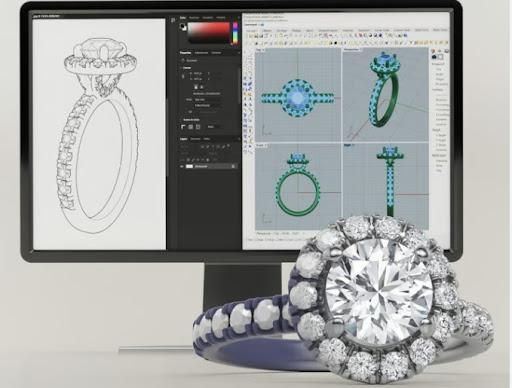

If you're looking for a specialty jewelry piece that is sure to make an impression but is still cost effective, then 3D printing is the answer. 3D printing allows for complex designs that otherwise would be too expensive or prohibitively time consuming to produce through traditional manufacturing methods. With the recent rapid advancements in 3D printing and design technology, jewelry makers now have unprecedented opportunities to turn their ideas and designs into reality.

Why 3d Modeling?

3d jewelry modeling is becoming increasingly popular for jewelry designers and small businesses alike. 3D printing technology enables jewelers to produce custom-made, intricate and unique pieces with intricate details at relatively low cost. Not only does 3D printing enable designers to create pieces that are not achievable with traditional techniques, but it also allows them to create pieces from start to finish without having to rely solely on the production team. Other reasons to know:

1. Uniqueness:

3D printing allows jewelry makers to create custom, unique designs that cannot be replicated by traditional manufacturing methods. This is ideal for those who want a one-of-a-kind piece.

2. Efficiency:

3D models can be created and printed quickly, as opposed to waiting for large bulk orders to be filled. The shorter production time leads to faster turnaround and greater efficiency.

3. Cost-Effectiveness:

3D printing is one of the most cost-effective methods of producing jewelry pieces. Because it eliminates the need for specialized materials and labor, the cost is drastically reduced.

4. Opportunity to Experiment:

Designers can use 3d rendering animation to prototype ideas before committing to a full-scale production. This gives them the chance to try different designs and materials before committing to a finished product.

5. Quality:

3D models are produced with precise accuracy and high-quality materials. This ensures that the final product is of a superior quality.

6. Flexibility:

3D models offer flexibility for designers to quickly adjust their designs. They can modify details or make changes to the overall shape and form of their piece without the need for costly re-tooling.

7. Accessibility:

3D models can easily be shared and distributed online, allowing jewelry makers to reach out to a larger audience. This is especially helpful for new and upcoming jewelry designers who want to showcase their designs to the world.

8. Versatility:

3D models can be used to produce a wide range of jewelry items, from rings and bracelets to earrings and necklaces. This allows designers to explore different styles and materials to create a truly unique piece.

9. Conservation:

It takes less energy and resources to produce jewelry through 3D printing compared to traditional methods. This makes 3D printing a greener and more sustainable choice for jewelry production.

Overall, 3D printing from Jewelry rendering service is quickly becoming a go-to method for jewelry makers to produce unique, high-quality pieces. With its cost-effectiveness, versatility, and customization options, jewelry designers can easily create one-of-a-kind pieces that stand out from the crowd. So if you're looking to make a statement with your jewelry, then 3D printing is the perfect choice.

StableDiffusion

StableDiffusion Photo by

Photo by  Photo by

Photo by

full parking

StableDiffusion

full parking

StableDiffusion