Many organizations utilize 3D printing, a type of added substance fabricating, for prototyping or turning out creation parts. It is a PC based interaction that sets down many more than one layer of an item until it is finished. The interaction utilizes metal or plastics and starts with a 3D computerized model of the last article.

Below are the some of the top 8 tips to maintain the quality of your 3D printer: -

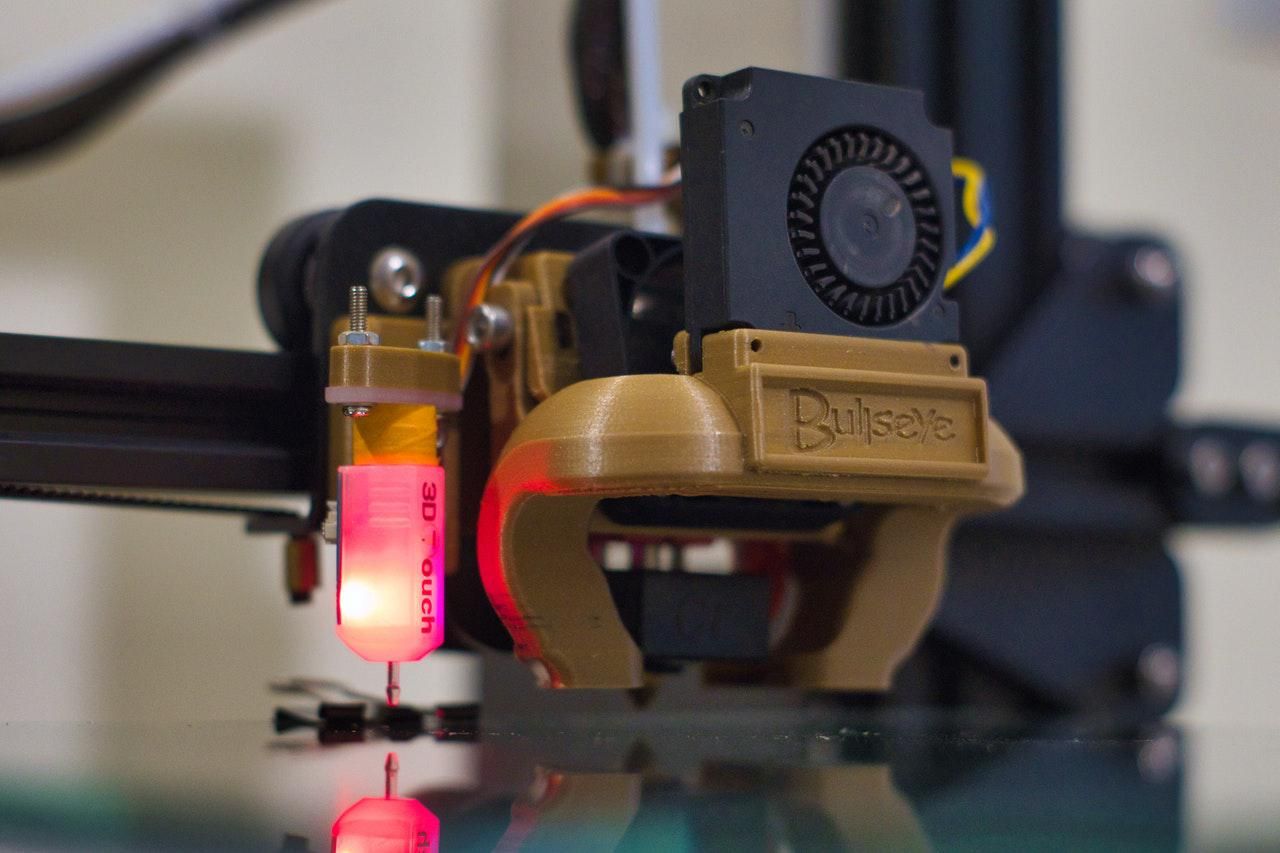

1. Adjust the nozzle

The most straightforward approach to further develop 3D print quality is to guarantee the bed is evened out and spout distance is appropriately set. Most printers accompany a suggested distance among bed and spout. An antenna check or a straightforward piece of paper can help in setting this distance.

When the spout is appropriately situated, the measure or paper should slide under the spout. No power is expected to get it to go under the spout. This interaction ought to be rehashed somewhere multiple times to guarantee that it's functioning admirably.

2. Check temperature and nozzle regularly

The spout temperature, and there could be a few spouts, influences print quality. In case it is excessively hot, there will be fiber strings between separated parts. On tall pieces, high temperatures normally dissolve the top layers and distort the last item.

3. Use plates

Distinctive form plates make various surfaces on the article. Bed materials like PEI, glass or Kapton tape ordinarily leave a smooth surface. Painter's tape or polycarbonate sheets depart a matte completion.

4. Pay more attention to maintenance

Each sovol sv01 3D printer has components and procedures that further develop print quality. Furthermore, printers ought to be kept up with to get the best print. For instance, the printer's rails ought to be cleaned and greased up. Also, the gantry ought to be at similar tallness on the two sides if your printer utilizes stepper engines. Additionally, verify whether there are any shaky areas in the casing.

5. Filament

Most filament are hydrophilic and retain water from the air, which messes printing up. Soggy fibers extend during expulsion since water becomes steam and escapes from the plastic. The fiber regularly pops or flies as the steam get away. There could likewise be smoke.

6. Slicer

Slicers convert 3D models into guidance sets that work the printer. Most are free.

7. Lower the speed

Echoes or ringing around the edges of element on the last article lessen the visual nature of your end result. These diverting lines are typically brought about by vibrations from the extruder's activity. To fix this issue, bring down the printing speed.

At long last, don't anticipate making wonderful items the initial not many occasions. Deal with your fiber. What's more, when with quality issues, audit your settings and make the vital changes gradually.