Taking on a over $373 billion dollar-a-year industry, Newlight Technologies is turning everyday carbon emissions into useable plastic.

With over 10.5 million tons of plastic being created every year in the US alone, our fossil fuels are converted in to oil-based plastics used all over the world. According to the Institute for Sustainable Communication, Of this 10.5 million tons of plastic waste created, only 1 to 2% of it is recycled, releasing over 14 billion pounds of trash into our world's oceans every year. Not only does this production create potential pollution-based environmental issues from lack of recycling, but this oil usage restricts our supply of fossil fuels, pushing oil companies for a high demand in resources.

Newlight Technologies

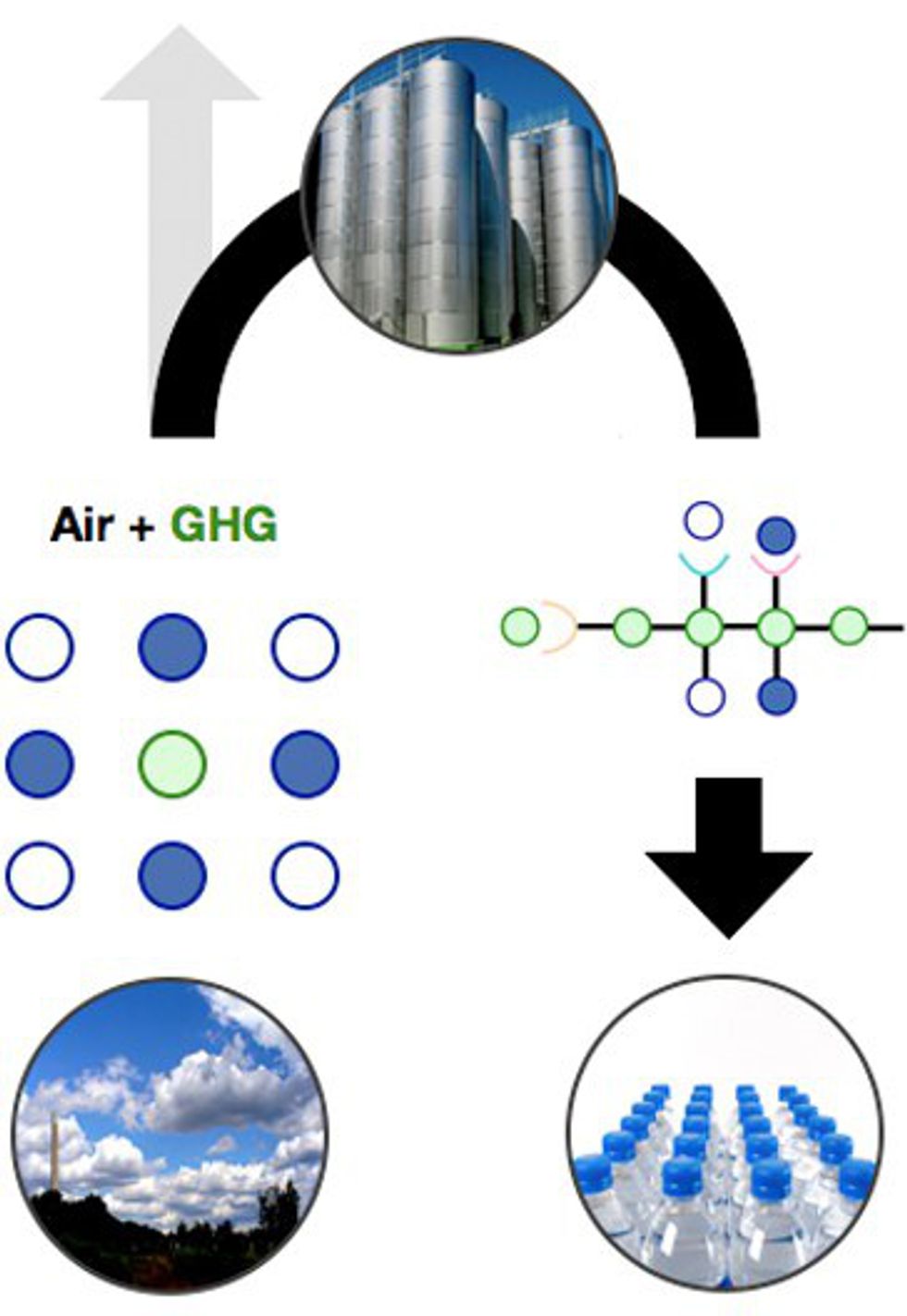

After ten years of extensive research and development, founders Mark Herrema and Kenton Kimmel of Newlight Technologies have created a carbon capture technology that combines air with methane-based greenhouse gas emissions to produce a plastic material firmly known as AirCarbon™.

AirCarbon™ has been verified on a cradle-to-grave basis, meaning that the affects of the products are environmentally designed from the beginning of their lives to their end. It is monitored as a carbon-negative material, including all energy, materials, transportation, product use, and end-of-life/disposal associated with the material, attributing to its positive environmental effects. By creating useful materials from harmful greenhouse gases, AirCarbon™ is redefining the plastic industry, pushing businesses to convert to more environmentally friendly ways of product production that is more cost effective.

"Newlight’s 9X biocatalyst generates a polymer conversion yield that is over nine times higher than the previous" as stated by Newlight Technologies. This production ratio also exhibits no negative feedback, making the production process environmentally safe. The weight of this revolutionary plastic is approximately 40% oxygen from air and 60% carbon and hydrogen from methane emissions..

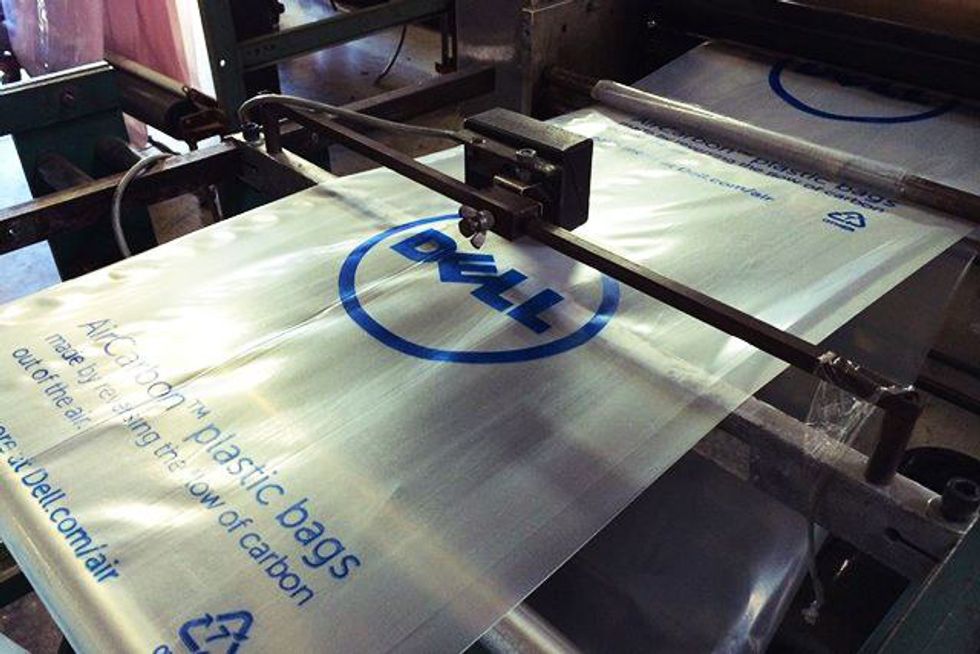

Within 24 months of reaching out to businesses in 2013, AirCarbon™ was adopted by a variety of leading companies including Dell, Hewlett-Packard, IKEA, KI, Sprint, The Body Shop, and Virgin to make packaging bags, containers, cell phone cases, furniture, and a range of other products. These products use greenhouse gases in a carbon-negative process as a cost-effective replacement for petroleum-based plastics.With this kind of technology being possible, why would any business choose creating new plastics that become pollutants to our oceans? The lack of knowledge and accessibility to technologies such as these prevent businesses from tapping into some vital resources that could change the effects of not only carbon on our environment, but the use of fossil fuels and amount of pollution created. As a future product designer, the amount of progress the product design and technology world has accomplished is truly outstanding. This inspiring way of thinking has made it possible to create products that are not only visually pleasuring, but have a unique functionality that is beneficial to both the user and environment. What do you think is possible with this growing technology? What does the future hold?